Reverse Engineering Services

You are not alone if you have questions about the reverse engineering process.The simplest way to describe the process is to picture a cube shaped object. When a 3D scanner captures the data from the cube it will capture tens of thousands to millions of data points depending upon the scanner used. Each face of that cube should be a perfect flat square, but the scanner captures every imperfection. If your end goal is to create a tool path to machine the cube, or even to create a mold for injection molding, you will want to have the data reverse engineered. During that process an engineer will use the scan data as reference to create an "idealized" or perfected representation of the cube. Instead of millions of points describing the cube, it will be modeled using only 6 perfectly flat, perfectly straight square surfaces. Those six surfaces are much easier for CAM software to interpret when it is generating a tool path. In addition, you would never want to reproduce any imperfections that can be found in existing objects. The scan data is a point cloud that can only be exported in file formats such as STL, OBJ or XYZ. If you need an IGES, STEP or parasolid file it will require reverse engineering or another process called NURBS surfacing.

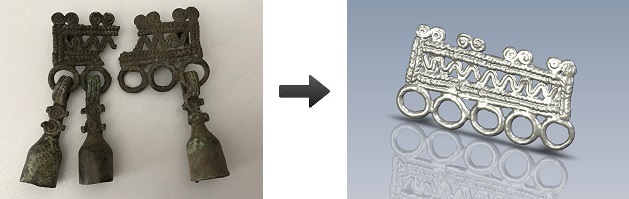

We also help customers who have broken or worn parts they need to machine or mold. We can correct the imperfections during the reverse engineering process. The example below shows a 1,000 year old Viking jewelry piece that was broken (left image).We scanned the object and repaired the fracture in the 3D model, which allowed our client to create a cast to reproduce the original jewelry. Our non-contact laser scanners are perfect for scanning valuable objects.

The final model is an idealized solid model which we can export as an IGES, STEP or parasolid (x_b or x_t) file. These files are compatible with most software packages such as AutoCad, Inventor, Geomagic, Maya etc. We can also transfer to Solidworks and provide a fully featured SLDPRT file. If you are unsure about how to take an existing object and turn it into your next design, let us help!